-

Wuxi Jianeng was founded in 1999. It has 24,000 square meters of plant, 38.28 million yuan of registered capital, more than 20 technicians and 100 employees.

Wuxi Jianeng was founded in 1999. It has 24,000 square meters of plant, 38.28 million yuan of registered capital, more than 20 technicians and 100 employees. -

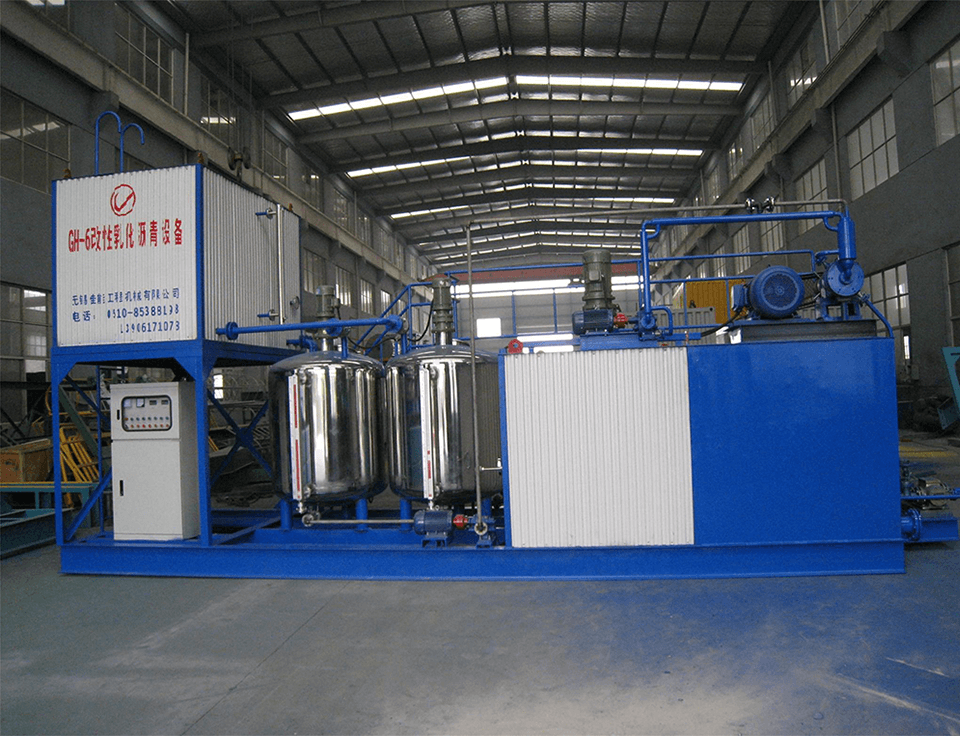

Wuxi Jianeng is specialized in the production of supporting equipment for asphalt mixing plant. Long-term cooperative customer includes LINTEC, AMMANN, NFLG, XCMG, MARINI, D&G, LYROAD, NIKKO and Tanaka.

Wuxi Jianeng is specialized in the production of supporting equipment for asphalt mixing plant. Long-term cooperative customer includes LINTEC, AMMANN, NFLG, XCMG, MARINI, D&G, LYROAD, NIKKO and Tanaka. -

Wuxi Jianeng has been engaged in engineering machinery equipment design and production for more than twenty years. With the pursuit of product performance, it has obtained a number of invention patents and Utility model patents, which have received unanimous praise in the industry.

Wuxi Jianeng has been engaged in engineering machinery equipment design and production for more than twenty years. With the pursuit of product performance, it has obtained a number of invention patents and Utility model patents, which have received unanimous praise in the industry.

Vertical bitumen tank for XCMG

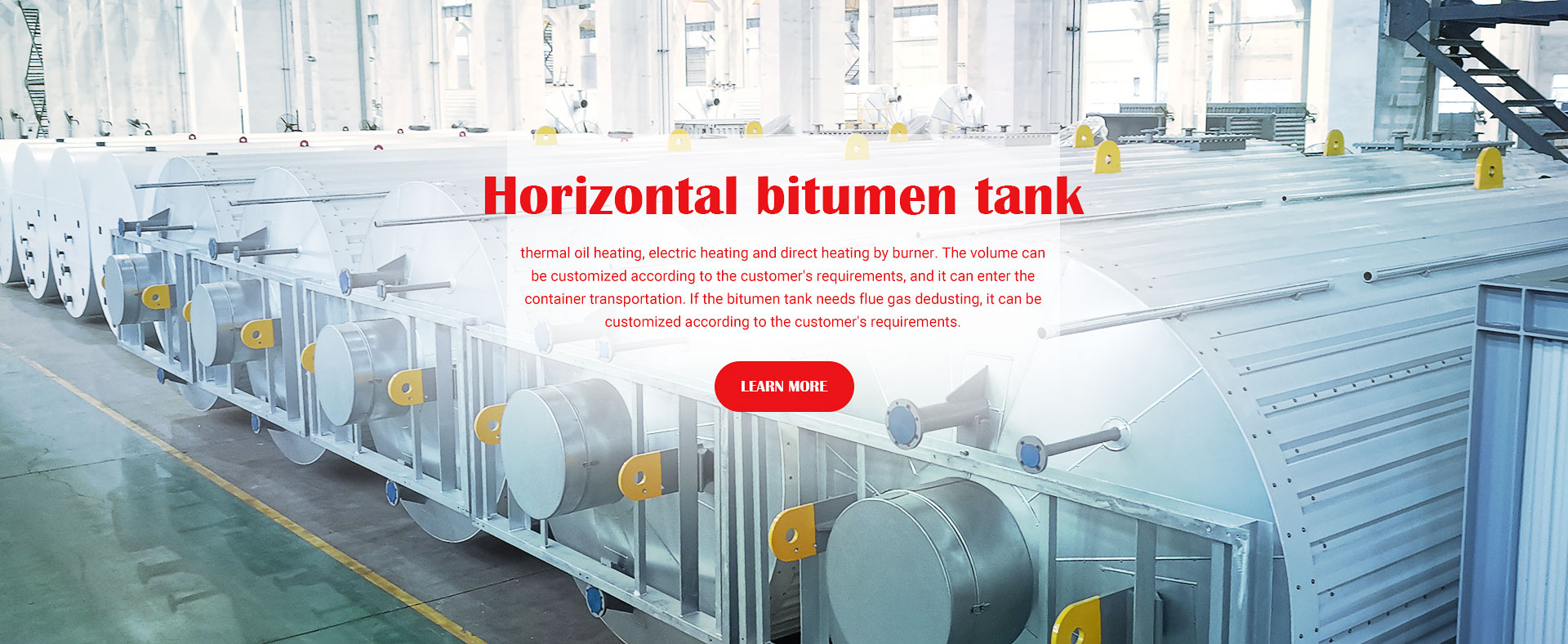

Horizontal bitumen tank for NFLG

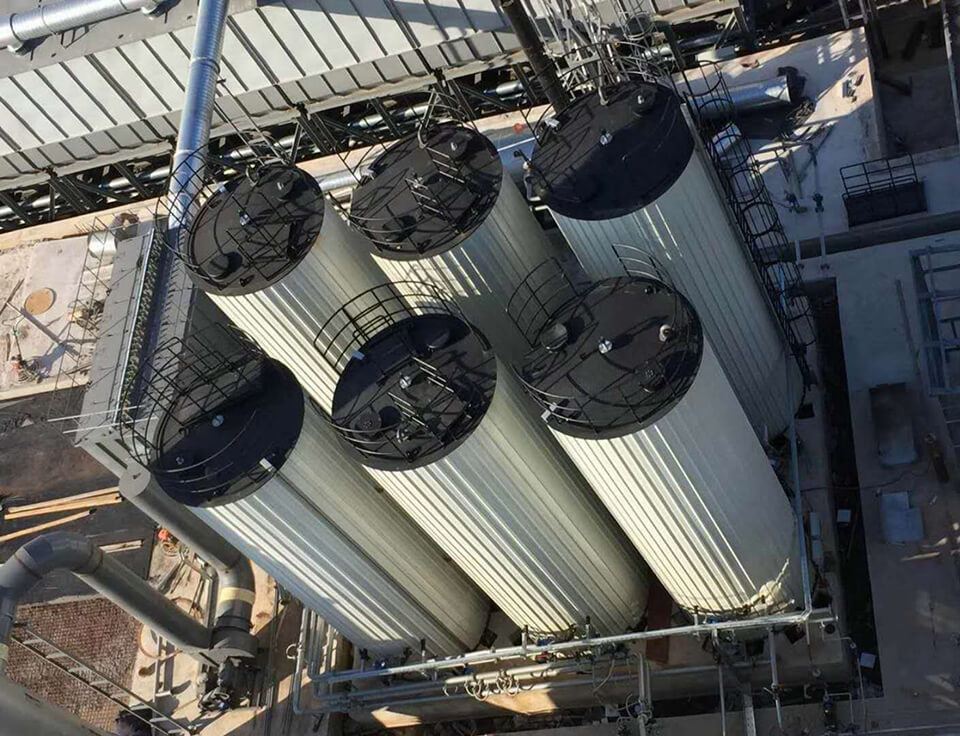

Hot storage silo for AMMANN

Vertical bitumen tank for AMMANN

Hot storage silo for Lintec

Horizontal bitumen tank for AMMANN

Vertical Bitumen tank for D&G

Vertical bitumen tank for D&G 2